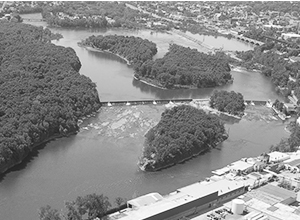

Pulp and paper manufacturers are among the largest users of water worldwide. Large quantities of water are required for the pulping process (reducing wood to a fibrous mat), the bleaching process (whitening and brightening the fibers), and the papermaking process (a slurry of 99% water conveys fiber onto a Fourdrinier paper machine).

In the U.S., water that is used in the pulp and papermaking process is collected and treated before it is returned to the environment. At Mohawk, water is continually recycled for reuse within the mill. Water that can no longer be used will undergo water treatment processes prior to discharge.

Water

Stock Check

Log In

If you are having trouble logging in please clear your browser cookies.

Don't have an account?

Register

Mohawkconnects.com will be performing scheduled maintenance on Saturday, January 20th, 2024 between the hours of 9am and 12pm EST.

We apologize for any inconvenience or interruption to stock check, Xpress Check, product pages and the add to cart feature during this time. If any issues persist beyond this window, please contact [email protected] or 800-THE-MILL during normal business hours resuming Monday, January 22nd at 8am EST. Thank you.