A Perfect '10': Building the Ideal Digital Press Operator

Name the industry that employs almost 450,000 individuals, accounts for more than 25,000 establishments and is larger than the music, video game and online advertising industries combined?

If you guessed print, you are correct.

Staffing challenges facing the print industry

But in spite of these impressive statistics, it’s no secret that the printing industry is facing its share of challenges:

- Aging workforce.

An estimated 66% of press crews are 45 years of age or older and trending towards retirement. In fact, a survey of Printing Industries of America (PIA) Affiliates found that 50 percent of respondents estimated a significant amount of their workforce (30-50 percent) would retire in the next 5 to 10 years. This emphasizes the critical nature of succession planning. - Finding the next generation of young talent.

The industry is still feeling the aftereffects of the 2007 recession, which effectively dried the talent pipeline. Employers were forced to enact hiring freezes and staff reductions. Many university curriculums and apprenticeship programs were cut, limiting exposure and opportunities for up-and-coming talent.

An exciting industry in transformation

But not all is doom and gloom. Truth is, the printing industry is at a very exciting juncture in its history.

- There’s big pockets of growth opportunities (3D printing, production inkjet and package printing, just for starters).

- Automation is becoming more widespread.

- The transition from analogue to digital processes is nowhere close to its saturation point.

With these new opportunities comes the need for a new type of digital press operator.

10 traits and skillsets of the perfect digital print operator

Whether you’re a young professional looking towards the print industry as a potential life-long career, or you’re a print shop owner looking for new talent, here are some of the traits needed for the new breed of digital print operators.

- 1Thirst for continuous learning. The printing industry has always been a craft industry predicated by hands-on experience. According to a PIA Affiliate survey, 85% of skilled talent is brought up-to-speedthrough on the job training (OJT) methods. This is one reason why job seekers can enter the industrywithout formal print education, and why employers can look for talent outside traditional printingprograms. However, as printing technologies and techniques change, press operators should have adesire to stay abreast of industry developments through continued training, industry publications,seminars, workshops and peer groups.

- Attention to detail. Print is a manufacturing process. As such, press operators must have a keen eye for detail. This means having an above average visual acuity to assess image registration, alignment,color accuracy and quality. Failure will result in wasted output, dissatisfied customers and profit losses.

- Problem-solving. When problems arise, what separates an average print operator from a great one is their ability – and willingness – to problem solve. This spans everything from troubleshooting equipmentissues (evaluating decision trees to identify likely root causes from hundreds of possibilities) toproactively assessing workflow processes (job priority and sequencing may need to be altered in orderto meet delivery deadlines). Solutions to problems may not always be blatantly obvious and may requiretrial and error. For instance, fusing temperature may need to be gradually lowered to correct papercurling, while transfer values and stock settings adjusted for printing on textured substrates.

- Understanding of basic print principles. While certain skills can be learned over time, operators that have a basic familiarity of printing processes and concepts will naturally have an advantage. Thisincludes understanding calibration, color density control, color management theories, imposition,collation, finishing techniques, and substrates.

- Decision-making. In many cases, print operators are tasked with decisions that can drastically impact the reputation – and profit margins – of their company. For instance, to maximize productivity anoperator may choose to group jobs that share similar qualities – such as inks, paper and post-pressrequirements – effectively minimizing job set-up, touches and changeover. Similarly, operators mustdecide how to handle jobs when errors are spotted despite proofs being signed off by a client.

- Cross-functional skills. As technology continues to evolve, it is beneficial for press operators to have a general understanding of processes both up- and down-stream. This means familiarity with creativedesign software, variable data, cross-media, workflow and post-process finishing.

- Proficiency with numbers. Much of a print operator’s daily routine involves working with numbers. For example, preparing production schedules or job sequencing may involve estimating how long a job willtake based on the number of copies required, average speed of the press, job preparation, projectedstoppages and job deadline. Similarly, when preparing a price estimate, the operator must calculate theamount of paper required, the dimension of the printed items, and forecast waste as well as the amountof time required to run the job.

- Organization. Because many printing companies operate several production shifts, press operators must stay organized – both for their own benefit and to help other team members. This includes leavingnotes to inform previous or upcoming shifts of job statuses, equipment issues or specification changes.Operators should also maintain daily data reports documenting operational levels, paper wastage anddowntime, which promotes an environment of constant improvement.

- Stress tolerance. Print environments are fast-paced, labor-intensive and deadline oriented. The ability to work quickly under pressure and deliver on tight timelines is greatly valued.

- Proactive. Given the nature of their work, digital press operators should be self-starters that can work independently without supervision. It is critical that they take initiative when it comes to equipmentmaintenance and preventative care. All digital presses have specific maintenance schedules intendedto help maximize print capacity and efficiency while minimizing risk – but these routine procedures don’ttake care of themselves.

Where can I find Skilled Digital Print Operators?

- Local universities: Many universities and trade schools have mandatory requirements for internship programs. Reach out to schools in your local area and find out how you can get involved.

- Industry staffing websites: There are several online networks that specialize in pairing employers and skilled workers within the print industry. A simple Google search will yield many reputable job placement sites.

- Scholarship foundations: Look to industry foundations that provide scholarships and career opportunities to youth interested in pursuing careers in print. You’ll find contact information for board members, most of whom occupy industry positions, who may have recommendations on scholarship recipients you can contact. Among the largest are PGSF and EDSF.

- Transferable skills: Your next digital print operator doesn’t need to come from a background in print. Instead, look for talent with transferable skills in similar or adjacent industries, such as automotive, manufacturing or medical imaging. This can help expedite ramp-up and training.

Suggested Articles

Name the industry that is valued at nearly $900 billion globally and drives $3.8 trillion in related services.

If you guessed print, you are correct.

In the past two articles we have covered the traits that make a great press operator; and the skills necessary to become a successful print sales person. But what about the person in charge of the entire operation?

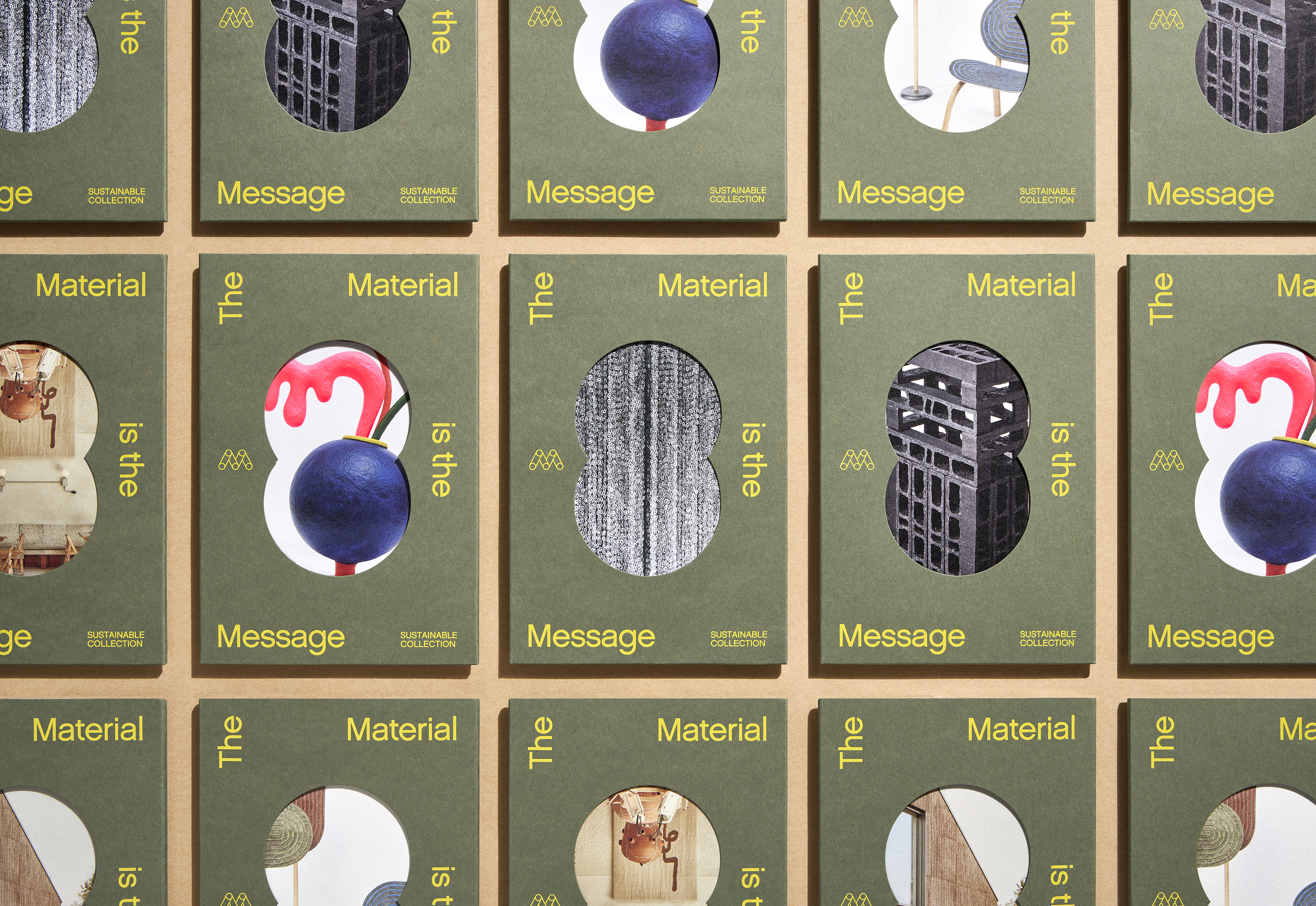

As digital printing evolves from compromise to sophisticated tool—advances in color, texture, and fiber papers push the boundaries of what's possible.