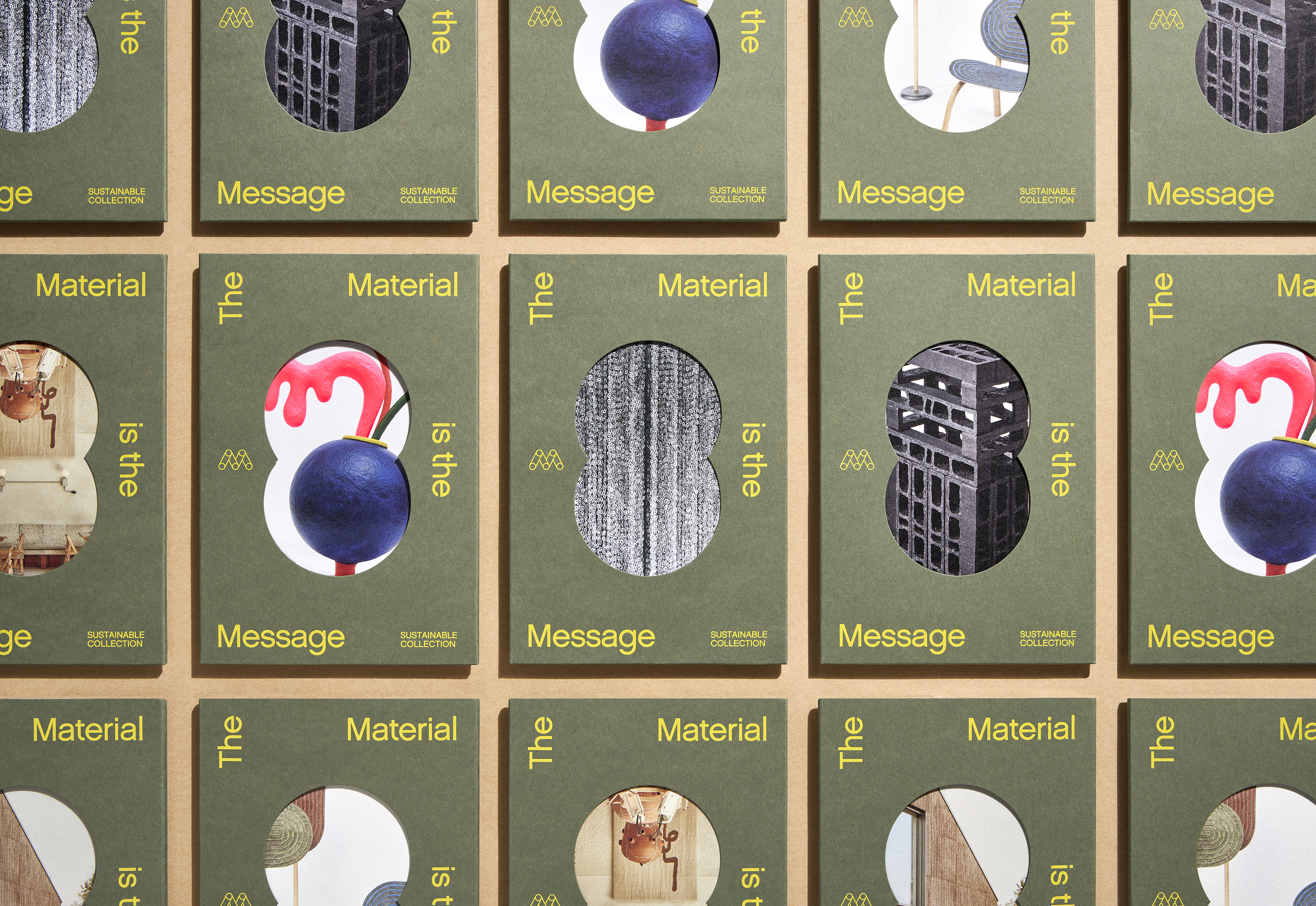

Designing Sustainably to Create Responsibly

Thoughtful, clever, and sustainable solutions for responsibly made, green print and packaging design.

Create to Last

Patagonia is the gold standard when it comes to environmental ethics. The company recognizes the importance of creating high-quality, made-to-last goods. But when you're out adventuring, gear can tear, break, and become damaged. Knowing many are in the habit of simply throwing things out, Patagonia encourages customers to send back goods for repair through their Worn Wear service.

By extending the life of their gear, Patagonia helps cut down on carbon, water, and waste related to manufacturing brand-new products. "Drop it in the mail, not in the landfill," they say.

These thoughtful, clever solutions go beyond materials and sourcing, tackling the challenge of waste from different angles. For additional tips for creating responsibly, visit A Better Source.

Suggested Articles

Craft and intentionality from product to packaging.

Eco-inks are vegetable and algae-based printing inks for paper and planet.